Client

Mr. Neil Price- Managing Director

The Box Factory

Unit 2,

Caswell Road

Leamington Spa

Warwickshire

CV31 1QD

Sponmech Project Number S10348

Date of initial enquiry February 2015

Date of fitting enclosure 17th June 2015

Date of Report Submission 22nd June 2015

Project Brief

Following e-mail contact from Mr. Price a quote was produced and subsequently an order placed for an acoustic enclosure to limit the environmental noise pollution emitted from 1 box printing and folding machine.

A site visit was made in February 2015 to acoustically and mechanically assess the noise problem and to collect sufficient data to ensure a suitable control measure.

Acoustic Measurement:

The following equipment was used to take readings from source.

Meter: Pulsar Instruments Assessor Model 82A

Serial No. 28486

BS EN 61672-1:2003 Class 2

Calibration Date 31/05/2015

Microphone: Pulsar Instruments Model MK216

Serial No. 112224

Calibration Date 31/05/2015

Site Calibrator: Pulsar Instruments Model 106

Serial No. 53984

IEC 60942:2003 Class 2

Calibration Date 31/05/2015

Recordings taken source show the Leq being 84.1 dB

The ambient noise level in the surrounding area was 66.4 dB

Noise over background level 84.1-66.4 = 17.7 dB

Therefore the perceived noise emitted from the machine is doubled by a factor of 17.7

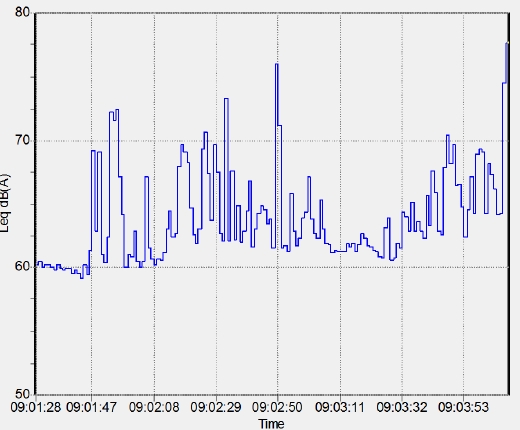

Back ground noise level 1m from machine (machine not running), other machines, plant and people working as normal.

Noise level 1m from machine (machine running), other machines, plant and people working as normal.

Control of Noise

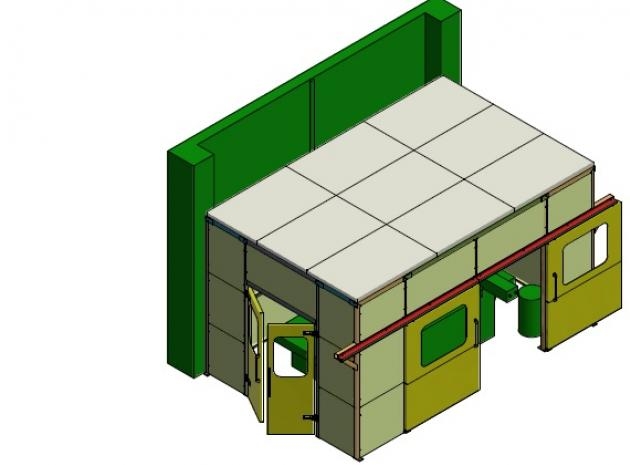

To reduce the noise output from the Machine an enclosure covering all open sides was constructed using steel as the acoustic barrier and mineral wool and the dissipation medium.

The enclosure was fitted around the top front and sides of the condensers fixing to a cavity brick wall to the rear and sitting atop cast concrete slab floor.

Results from Post Fitting Survey

After fitting of the enclosure was completed the noise readings were taken both inside and outside the enclosure.

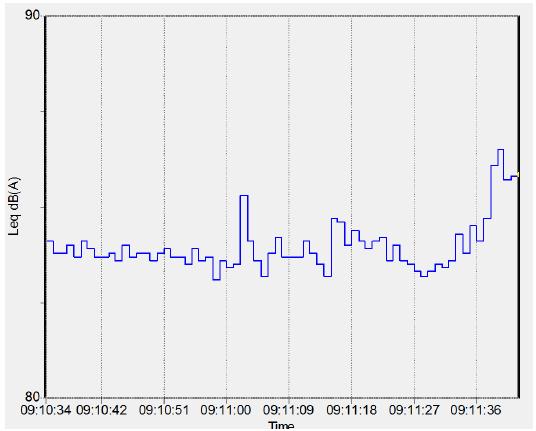

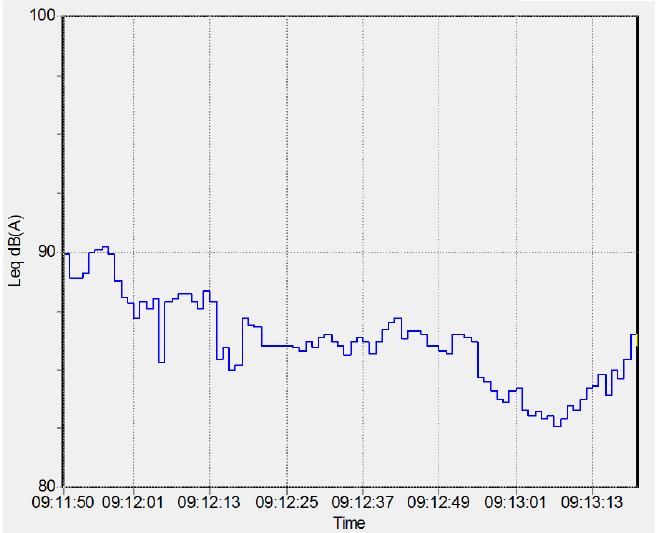

Noise level inside the enclosure (With machine running) 84.1dB.

Noise level 1m outside the enclosure (With machine running) 77.0 dB.

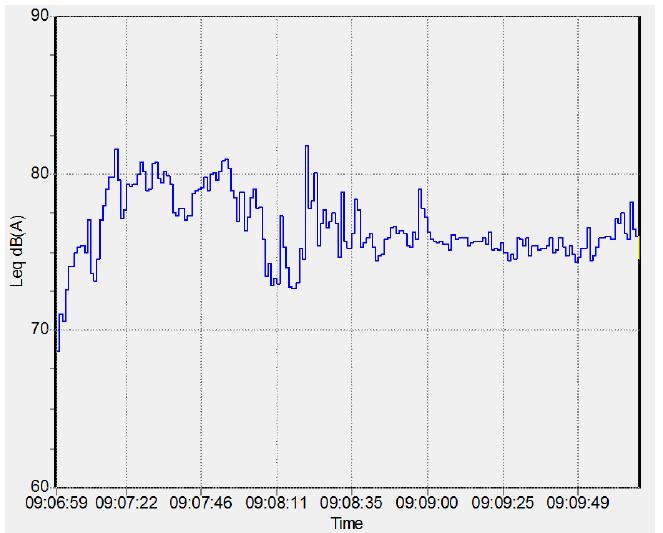

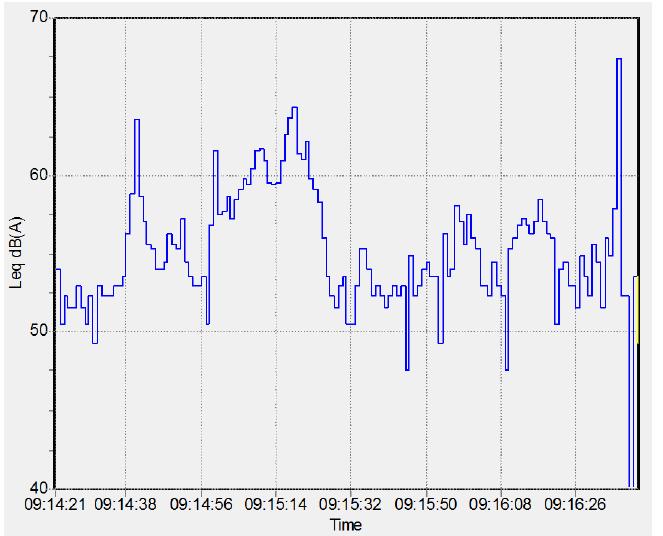

Noise level corner of carpark approximately 20 m for neighboring property on Clapham terrace (machine running),other machines, plant and people working as normal. (N.B. 09:14:38-09:15:32 the higher reading is due to hgv entry to premises and the spike at the end of the was air system exhausting on hgv).

As a result of the enclosure being fitted there will be no noticeable difference to neighbouring residents when the machine is running.

For and on behalf of Sponmech Safety Systems Ltd.

Stuart Humpage