Sponmech Safety Systems looks at the latest prosecutions charged against companies who have failed to comply with current machine safety regulations.

Apprentice loses two fingers

A timber mouldings manufacturer in Rochdale has been fined after a young apprentice lost two fingers while working on machinery.

The 16 year old was working alongside an experienced colleague on a moulding machine at Dresser Mouldings (Rochdale) Ltd in July 2014, when a piece of wood jammed.

The machine was opened and the apprentice was looking inside to adjust the machine when his gloved right hand caught on the rotating centre blade.

His right hand was severely injured, and he lost the entire middle finger and part of his thumb.

HSE found that the company had failed to effectively prevent access to the dangerous parts of the machinery.

Dresser Mouldings (Rochdale) Ltd pleaded guilty to breaching Section 2 (1) of the Health and Safety at Work Act 1974 and was fined £18,000.00 with costs of £844.50.

Worker’s hand caught in lathe

An employee was injured when his hand was caught on the moving parts of a lathe at an Ayrshire factory.

Gordon Campbell, an experienced CNC turner, was working on the lathe at Omnitool Ltd to produce a component for use in the oil and gas industry. The lathe was fitted with interlocking safety doors to prevent access to the moving parts but they had been disabled and the door was open to allow him to see work progressing on the component.

A piece of metal cutting came loose but when Mr. Campbell reached in with pliers in his right hand to remove it, his hand came into contact with the rotating part of the lathe. He pressed the emergency stop button with his left hand and was taken to hospital after being given first aid. He suffered cuts and tendon damage.

HSE found that the company had assessed the risks of various tasks within the factory and interlocking safety doors were fitted to the lathe but they were deliberately disabled by the company.

The court heard that the lathe had been operating without the interlocks for around six years to allow operators to see inside. The doors had been fitted with a glass panel, but over time this became scratched so viewing the work became difficult, HSE said.

Omitool Ltd pleaded guilty to breaching Regulation 11(1) and (2) of the Provision and Use of Work Equipment Regulations 1998 and was fined £4,700.00.

Paper shredding firm prosecuted

A new employee suffered severe injuries to his hand when it came into contact with a mobile paper shredding machine.

In December 2013 Stuart Rolls, who had only worked for Shred-it Ltd in Buckinghamshire for two weeks, was alone in the shredder area. He tried to free a piece of paper from the machine but his right hand came into contact with shredder knives. He lost a finger, part of his thumb and the top of another finger.

HSE found that the firm had failed to effectively prevent access to the dangerous parts of the machinery.

Staff bypassed interlocked guards

A Kent firm has been prosecuted for allowing workers to bypass interlocked guards on machinery after one employee trapped his hand.

HSE said that the Swan Mill Paper Company Ltd was aware that engineers would use interlock keys to override the guarding on machines for the purpose of diagnosing faults.

One engineer injured his fingers when his hand became trapped after he defeated an interlocked door to get a better look at a wrapping fault in January 2013.

At least three members of the company’s maintenance team had interlock keys for bypassing and defeating interlocks on the machines. HSE said it was common in industry and companies were often under the misleading impression that, if carried out by an engineer, such practice was safe.

Swan Mill Paper Company was found guilty of breaching Regulation 11 (1) of the Provision and Use of Work Equipment Regulations 1998 but acquitted of another charge under Regulation 22. It was fined £5,000.00 and ordered to pay £22,000.00 in costs with a victim surcharge of £120.00.

The Health and Safety Executive (HSE) estimates that inadequate machine guarding causes over 40,000 injuries every year. Some of those injuries can be fatal. In order to prevent these incidents from happening, the HSE recommends that employers should "take effective measures to prevent access to dangerous parts of machinery".

Regulation 11(1) of The Provision and Use of Work Equipment Regulations 1998 states: Every employer shall ensure that means are taken in accordance with paragraphs (2) which are effective.

A. To prevent access to any dangerous part of machinery or to any rotating stock-bar; or

B. To stop the movement of any dangerous part of machinery or rotating stock-bar before any part of a person enters a danger zone.

This is why all our standard Lathe, milling, drilling, grinding, and slotting machine guards are fitted with interlocks as standard.

Employers who neglect their duty to protect workers will continue to be held accountable. Just think, what could cost a little now, could save a lot in the future.

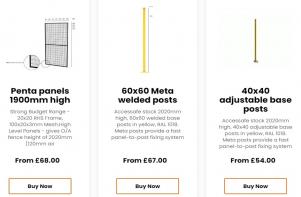

Customers can now purchase stock perimeter mesh machine guarding and warehouse partitioning from our sister company Accessafe UK Ltd.

https://accessafe.co.uk/shop/standard-access-guarding

READ MORE

NEW 2022 Access S.r.l Catalogue - all items available to pre-order from Sponmech

READ MORE